Morsa 3D Printig Wax Filament

When used for lost wax casting, the burnout is extremely clean (much better than using plastic filament). This product can also be polished, machined, and carved MUCH easier than plastic filaments.

Morsa 3D wax is softer than traditional plastic filaments. Because of this, some extruder feed drives may need to be modified in order to properly feed the filament. The easiest way to determine if your printer will need any modification is to find out if other people are already using any of the flexible filaments on your machine. Many of the rubbery, flexible filaments on the market are even softer and more flexible than Morsa 3D Wax filament. Because of this the modifications necessary for them also work well for Morsa 3D Waxt filament. There are two key points to keep in mind when printing softer filament material.

1. Guide the filament through the entire drive to prevent curling.

2. Provide proper tension on the guide arm bearings that presses the filament into the drive gear to prevent grinding.

For bed adhesion, our personal experience has had the best results using multiple layers of "extra super hold" hair spray on a heated glass bed. We recommend spraying the glass with 6 light coats, letting them dry in between coats.

A second option for bed adhesion would be to use cloth athletic tape or gaffers tape.

Here are a few startup recommendations to help get you started. Please keep in mind that these suggestions can be dependent on both your printer design and the geometry of the object you are printing.

- Extrusion temperature = 140°C-150°C

- Bed temperature = 80°-90°C

- Shells = 2-3 (for most models)

- Print speed is typically 20 to 70mm/s

- Prints best when layers have enough time to cool. This can be achieved in several ways. A skirt/brim with all layers, active cooling fan (on low), printing multiple identical items, sacrificial pillar, or extra pause time between layers. A caution here is to not cool too fast. This will cause exaggerated warp.

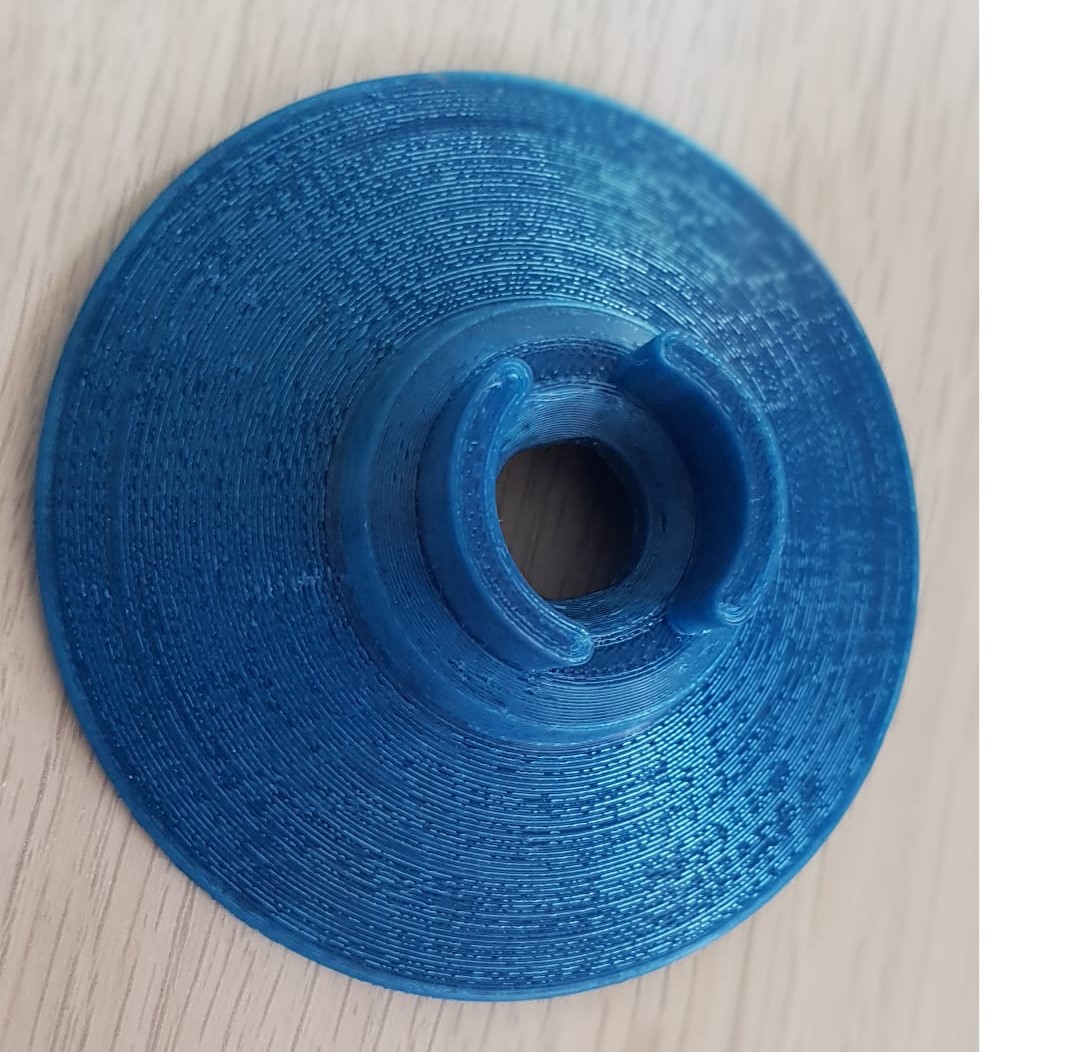

Packaging:

1kg spool 1.75mm

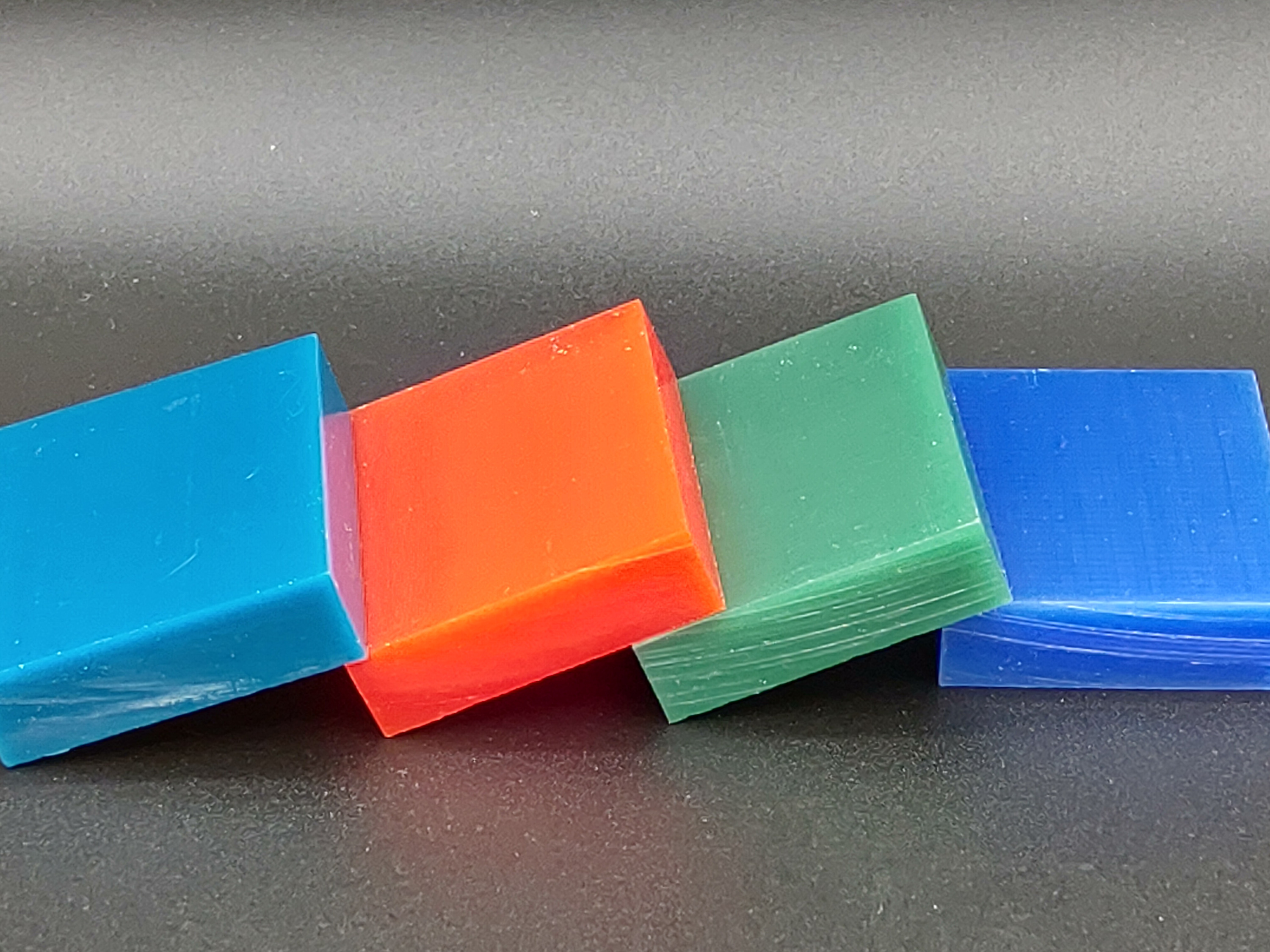

Morsa 3D Milling Wax

Morsa 3D Milling Wax disks are a slightly more waxy and carveable formula for Dental CAD/CAM applications. Our machinable wax for dental CAD/CAM is put through an additional manufacturing step that we call MicroFine. The result is a machining wax that gives you the ability to create exceptional detail and have a minimum of cleanup after you are finished.

Packaging: pack of 6 disks 50mm x 100 mm

USP MOR-Print

- Free from fillers and suspended solids

- No shaking necessary - no bubbles in the liquid - R2P READY TO PRINT

- No sedimentation during production time

- MMA free

- Tested biocompatibility according to EN ISO 10993-1 for medical products

- Odourless and tasteless

- Free of colour pigments

- Homogeneous formulation

- Made in Germany - production on site in Lütjenburg

- Production of non-medical products as well as medical products of classes 1 and 2a

- Production according to medical product standards

- In-house R&D for development and further development

- Material savings through additive technology

- Shelf life up to 3 years (depending on product)

MOR-Print Cast

- Burns without residue

- Distortion-free even with large objects

- Matched to phosphate-bonded investment materials

- High strength, dimensional and edge stability

- Precise reproduction with finest surface structure

MOR-Print Model

- Models of all kinds, from situation models to die models

- Implementation of digital data sets as a substitute for impressions

- High efficiency - low viscosity resin setting for optimised material consumption and short post-processing time

- Good scannability

- Good readability due to opacity